Plastic Compounding Market Size, Segments, Share and Companies (2025-34)

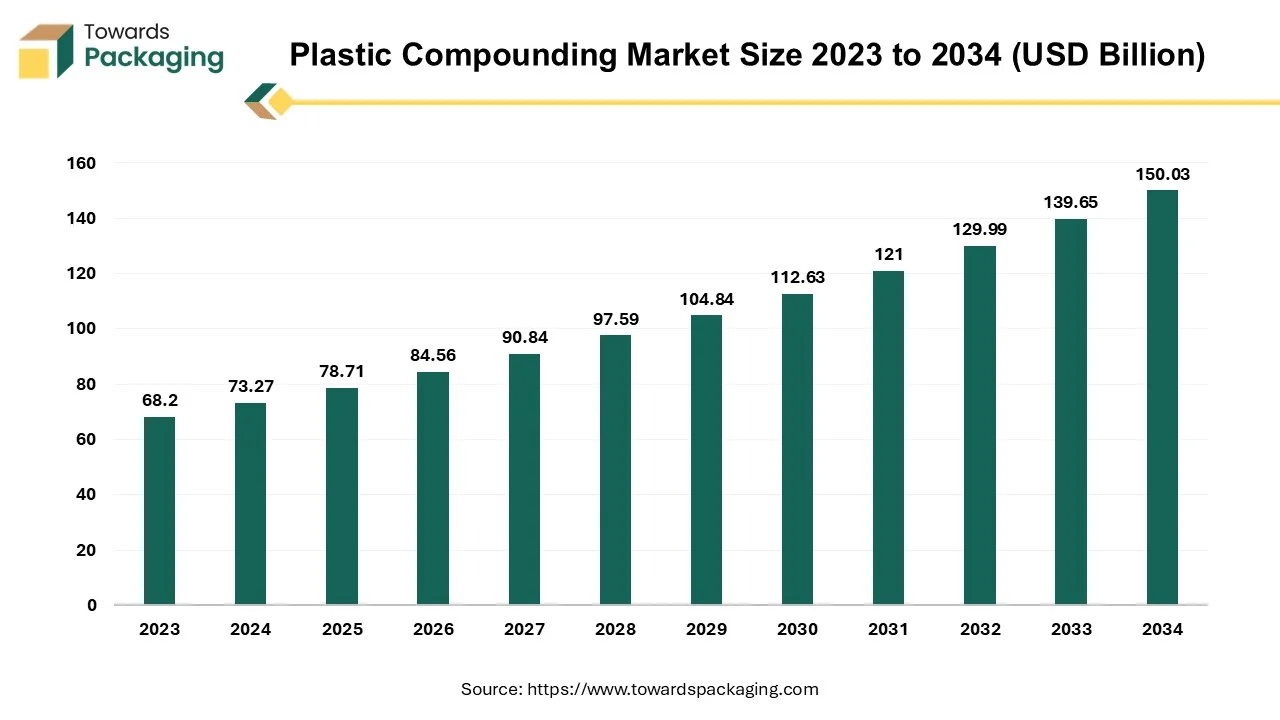

As detailed in the latest report by Towards Packaging, the global plastic compounding market is forecast to grow from USD 84.56 billion in 2026 to about USD 150.03 billion by 2034, at a CAGR of 7.43% between 2025 and 2034.

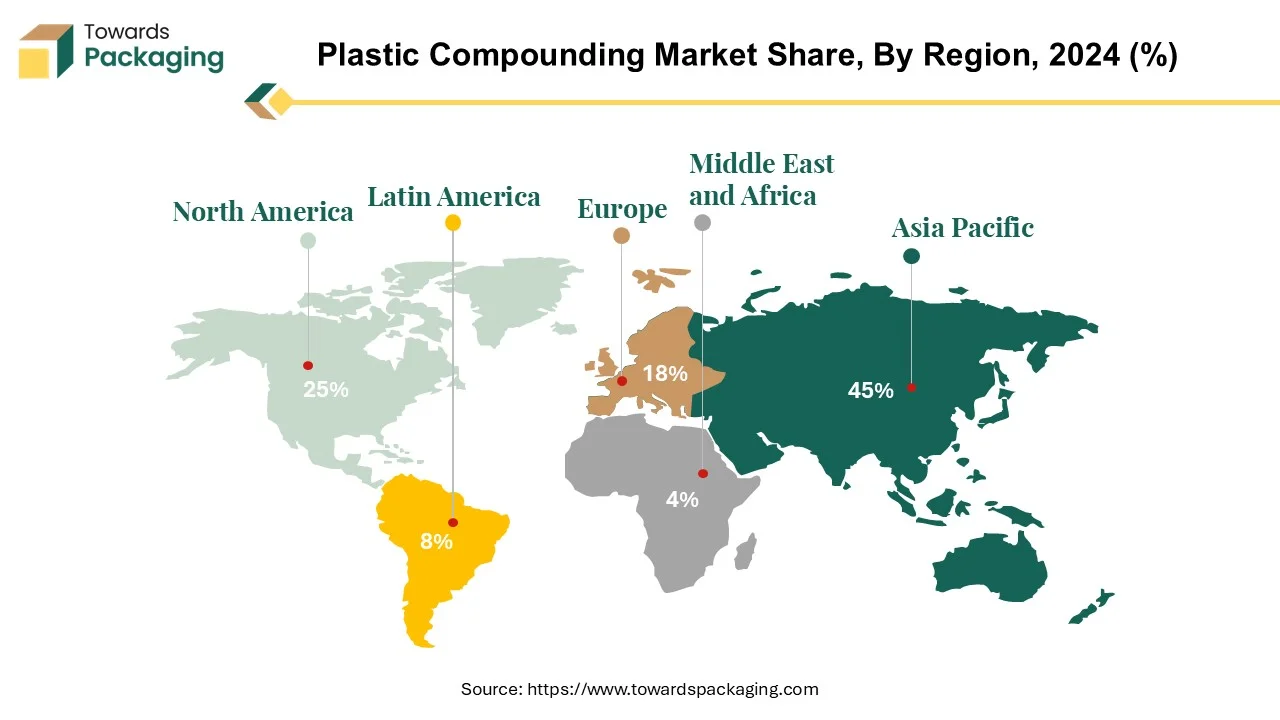

Ottawa, Oct. 29, 2025 (GLOBE NEWSWIRE) -- The global plastic compounding market, which stood at USD 78.71 billion in 2025, is projected to grow further to USD 150.03 billion by 2034, according to data published by Towards Packaging, a sister firm of Precedence Research. We quantify demand by source (fossil-based 57% share in 2024, recycled fastest-growing; bio-based scaling), product (PP 31% share in 2024, PE fastest; plus PVC, PS, PET, ABS, PC, PA, TPO/TPV, etc.), and application (automotive 26% in 2024, packaging fastest). Regional coverage spans North America, Europe, Asia Pacific (leader at 45% in 2024), Latin America, and MEA. Deliverables include competitive benchmarking (BASF, Dow, SABIC, LyondellBasell, DuPont, Covestro, LANXESS, Solvay, Asahi Kasei, RTP, Ravago…), value chain analysis (feedstocks → compounding → conversion), trade statistics and corridor balances, and manufacturer/supplier databases with capacity, grades, and footprints.

Request a Custom Case Study and Research Report Built Around Your Goals: sales@towardspackaging.com

What is Plastic Compounding?

Plastic compounding is the process of mixing raw plastic resins with various additives to produce a new material, known as a compound, with customized properties such as enhanced strength, color, flexibility, or durability. It drives innovation by transforming basic plastics into high-performance materials tailored for specific applications, including UV resistance, improved mechanical properties, and more. Compounding also plays a key role in sustainability by incorporating recycled content and developing eco-friendly formulations without compromising performance.

What are the Latest Trends in the Plastic Compounding Market?

-

Increased Demand for High-Performance Compounds for EVs and Electronics

As the EV and electronics sectors grow, the demand for materials with specific properties, such as electrical insulation, high heat resistance, and lightweight strength, is increasing to support safety, efficiency, and advanced functionality. In electric vehicles, components like battery enclosures, connectors, and wiring harnesses require specialized, high-performance plastics that can handle thermal and electrical demands. The heat generated by EV batteries and powertrains further drives the need for materials with excellent thermal stability and resistance.

-

Use of Nanotechnology to Improve Material Properties

Nanotechnology is a major trend in plastic compounding, as adding tiny amounts of nanomaterials drastically enhances material properties such as strength, durability, and even barrier performance. Nanocomposites decrease gas permeability and increase water resistance, which is mainly beneficial for food packaging applications. By creating materials with superior performance, nanotechnology permits plastic producers to target new, profitable markets and even applications that are previously unreachable.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5199

What Potentiates the Growth of the Plastic Compounding Market?

The growing focus on sustainable and recyclable plastics is expanding the market by driving innovation, opening new revenue streams, and meeting the rising demand for eco-friendly materials. However, recycled plastics often face quality challenges, such as inconsistencies in color, melt flow, and mechanical properties, due to contamination or material degradation. Similarly, bio-based and biodegradable plastics have unique characteristics that require specialized processing. Plastic compounders, with their advanced machinery and expertise, are well-positioned to address these challenges by blending raw materials with additives, reinforcements, and polymers to meet precise performance requirements for high-end applications.

Limitations & Challenges in the Plastic Compounding Market

Key limitations and challenges in the market involve stringent environmental regulations, raw material price volatility, complexities in recycling compounded plastics, high expenses for advanced technologies, and difficulties in maintaining consistent product performance. These difficulties are driven by factors such as supply chain disruptions, the need for sustainable options, and technical hurdles in processing and recycling materials effectively.

Regional Analysis

Who is the Leader in the Plastic Compounding Market?

Asia Pacific led the market by capturing the largest share in 2024 due to a combination of factors, including rapid industrialization and urbanization, a vast manufacturing ecosystem, and strong demand from key sectors such as electronics, automotive, and packaging. The growth of the electronics sector, mainly in China, fuels the need for plastic compounds in products such as smartphones and a few electronic devices. Competitive labor expenses and proximity to raw material suppliers make the region attractive for producers.

China Market Trends

China's market is experiencing significant expansion, driven by the automotive, construction, and electrical & electronics industries. Key trends include a strong need for engineering plastics in applications such as high-speed rail and aerospace, a rising focus on sustainable solutions like biodegradable and also recycled compounds, and the integration of advanced technologies such as Industry 4.0 to enhance efficiency.

Japan Market Trends

Japan's strong automotive and electronics industries drive the demand for technologically advanced compounds with improved thermal, mechanical, and electrical properties. A major trend is the advancement and adoption of sustainable solutions, including bio-based and recycled plastics, driven by government policies and public awareness.

How is the Opportunistic Rise of North America in the Plastic Compounding Market?

North America's opportunistic rise in the market is driven by the increasing need for high-performance and lightweight materials from numerous industries. A strong regional focus on sustainability and innovation in recycled and bio-based plastics is creating significant expansion opportunities. Thus, improvements in manufacturing, such as advanced twin-screw extruders and digital process control, are increasing efficiency and enabling the production of high-quality compounds. The usage of specialized additives can monitor compounds for specific needs, such as flame retardancy and thermal stability.

U.S. Market Trends

The market in the U.S. is growing due to factors such as the increasing need for lightweight and fuel-efficient materials in the automotive industry, as well as the substitution of conventional materials like glass and metal. Plastic compounds are increasingly replacing wood, natural rubber, metals, and glass in numerous applications because of their superior properties and versatility.

Canada Market Trends

The Canadian market is rising due to increasing need from key sectors such as automotive and construction, a strong focus on sustainability via recycled and bio-based polymers, and even technological advancements such as nanotechnology. There is a remarkable push to develop and use compounds made from recycled plastics and bio-based materials to reduce the environmental impact of conventional plastics.

More Insights of Towards Packaging:

- Returnable Transit Packaging (RTP) Market Size, Segments, Share and Companies - https://www.towardspackaging.com/insights/returnable-transit-packaging-market-sizing

- Food and Beverage Metal Cans Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/food-and-beverage-metal-cans-market-sizing

- Packaging Films Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/packaging-films-market-sizing

- Biopolymer Packaging Market Size, Regional Share (NA/EU/APAC/LA/MEA) and Competitive Analysis - https://www.towardspackaging.com/insights/biopolymer-packaging-market-sizing

- Plastic Cosmetic Packaging Market Size, Share & Trends - https://www.towardspackaging.com/insights/plastic-cosmetic-packaging-market-sizing

- Fiberboard Packaging Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/fiberboard-packaging-market-sizing

- Retail Shipping Labels Market Size, Regional Data (NA/EU/APAC/LA/MEA), Competitive Analysis, Value Chain & Trade Analysis - https://www.towardspackaging.com/insights/retail-shipping-labels-market-sizing

- Pre-Qualified Thermal Packaging Market Size, Segments and Regional Data (NA/EU/APAC/LA/MEA) - https://www.towardspackaging.com/insights/pre-qualified-thermal-packaging-market-sizing

- Canada Pharmaceutical Packaging Market Size, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/canada-pharmaceutical-packaging-market-sizing

- Commercial Printing Market Size, Segments, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/commercial-printing-market-sizing

- Fast-Food Containers Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/fast-food-containers-market-sizing

- Active Packaging Market Drives at 7.5% CAGR (2025-34) - https://www.towardspackaging.com/insights/active-packaging-market

- Packaging Tape Printing Market Size, Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/packaging-tape-printing-market-sizing

- BioProcess Container (BPC) Market Size, Segments, Regional Share (NA/EU/APAC/LA/MEA) - https://www.towardspackaging.com/insights/bioprocess-container-market-sizing

- Beverage Carton Packaging Machinery Market 2025 Update Shows Leadership by Tetra Pak SIG and Other Global Players - https://www.towardspackaging.com/insights/beverage-carton-packaging-machinery-market-sizing

- PET Trays Market Intelligence, Benchmarking, Consumer Insights and Growth Strategies - https://www.towardspackaging.com/insights/pet-trays-market-sizing

- Canada Household Packaging Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034 - https://www.towardspackaging.com/insights/canada-household-packaging-market-sizing

- Healthcare and Laboratory Label Market Size, Segments and Regional Data (NA/EU/APAC/LA/MEA) - https://www.towardspackaging.com/insights/healthcare-and-laboratory-label-market

Segment Outlook

Source Insights

The fossil-based segment dominated the plastic compounding market in 2024. This is due to its cost-effectiveness, established infrastructure, and versatile properties such as flexibility, strength, and durability. These factors have contributed to a strong industrial preference for conventional petrochemical feedstocks, like polyethylene and polypropylene, which are more convenient and even economical for large-scale production. Meanwhile, fossil-based plastics are usually more economical to manufacture compared to other options, which is a key consideration for producers.

The recycled segment is expected to grow at the fastest rate during the forecast period. This is due to sustainability pressures, rising consumer and corporate need for eco-friendly products, cost-effectiveness, and stricter regulations. Compounding allows recycled plastics to be modified with additives to meet specific performance needs, making them suitable for a broad range of applications and encouraging greater adoption. Enhancements in compounding technology enable the improvement of recycled plastics with additives to match or even exceed the properties of virgin materials. Thus, advanced recycling technologies are permitting the processing of more complex contaminated plastics, which were previously challenging to recycle.

Product Insights

The polypropylene (PP) segment dominated the plastic compounding market with the largest share in 2024. This is due to its excellent balance of performance, expense, versatility, and desirable properties such as being chemically resistant, lightweight, and durable. Thus, it is ideal for a broad array of applications, primarily in the automotive industry for parts such as bumpers and trims, as well as in flexible and rigid packaging. It is also utilized in consumer goods and electronics. Moreover, it can be easily processed using common thermoplastic methods such as injection molding, which permits creative designs and complex shapes.

The polyethylene (PE) segment is expected to grow at the fastest rate in the upcoming period. This is due to its versatility and wide applications in high-demand industries such as packaging, construction, and even automotive. Its durability, cost-effectiveness, and chemical resistance make it ideal for packaging. Additionally, its use in lightweight automotive components for fuel efficiency and its extensive use in infrastructure, such as pipes and drives, increases demand. Rapid industrialization and urbanization in regions such as the Asia-Pacific are significantly increasing the demand for polyethylene in various manufacturing and consumer goods sectors.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Application Insights

The automotive segment dominated the plastic compounding market in 2024. This is due to the industry's ongoing move to replace heavy metal parts with lightweight plastic compounds to enhance fuel efficiency and even reduce emissions. Strict government regulations on fuel efficiency and emissions are forcing automakers to find materials that help them meet these standards, making plastics a strategic option. Plastic compounds provide greater design freedom for complex shapes and are usually more resistant to corrosion and fatigue than metals. Thus, they can also be programmed to achieve specific properties such as high impact resistance and durability.

The packaging segment is expected to expand at the fastest rate during the forecast period. This is due to the increasing global need for innovative and sustainable packaging solutions, driven by a booming e-commerce market, a rising middle class, and the demands of the food, beverage, and healthcare industries. The rapid expansion of e-commerce needs a vast amount of packaging for delivery. The growth of the middle class and e-commerce platforms increases the need for both flexible and rigid packaging solutions. Asia Pacific, in particular, is a major growth driver due to rapid industrialization and a large consumer base.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in the Global Plastic Compounding Market

- In January 2025, PolyCycl, a circular economy start-up based in Chandigarh, launched its patented technology to convert hard-to-recycle plastics into food-grade polymers, renewable chemicals, and sustainable fuels.

- In February 2024, Peak Performance Compounding Inc. launched its Synnergy-brand compounds for medical and industrial applications. These new materials are a custom line of low-friction compounds designed for single- and dual-layer tube extrusion, injection molding, and blow molding. They are formulated with a proprietary blend of additives to lower the coefficient of friction (COF) in natural resins such as polyether block amide (PEBA) and thermoplastic polyurethane (TPU).

Top Plastic Compounding Market Players

- Ravago

- Polyvisions, Inc.

- Arkema

- KURARAY CO., LTD.

- Eurostar Engineering Plastics

- S&E Specialty Polymers

- RTP Company

- DuPont de Nemours, Inc.

- LyondellBasell Industries Holdings B.V.

- Washington Penn

- Covestro AG

- Asahi Kasei Corporation

- SO.F.TER

- Solvay

- LANXESS

- TEIJIN LIMITED

Segments Covered in the Report

By Source

- Fossil-based

- Bio-based

- Recycled

By Product

- Polyethylene (PE)

- Polypropylene (PP)

- Thermoplastic Vulcanizates (TPV)

- Thermoplastic Polyolefins (TPO)

- Polyvinyl Chloride (PVC)

- Polystyrene (PS)

- Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Polyamide (PA)

- Polycarbonate (PC)

- Polyurethane (PU)

- Polymethyl Methacrylate (PMMA)

- Acrylonitrile Butadiene Styrene (ABS)

- Others

By Application

- Automotive

- Building & construction

- Electrical & electronics

- Packaging

- Consumer goods

- Industrial Machinery

- Medical Devices

- Optical Media

- Aerospace & Defense

- Others

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Malaysia

- Philippines

- Latin America

- Brazil

- Rest of Latin America

- Middle East & Africa (MEA)

- GCC

- North Africa

- South Africa

- Rest of the Middle East & Africa

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5199

Request a Custom Case Study and Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Healthcare | Towards Automotive | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

Towards Packaging Releases Its Latest Insight - Check It Out:

- AI in Packaging Market Driven by 10.28% CAGR (2025-34)

- Aseptic Packaging Market Size, Share, and Forecast Analysis (2025-2034): Global Trends, Segments, and Regional Insights

- Dairy Aseptic Packaging Material Market Driven by 3.05% CAGR (2025-34)

- Compound Pharmacy Packaging Market Size, Segments, Share and Companies

- Plastic Liner Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Airless Pumps Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Packaging Printing Market Size, Key Trends, Technologies, and Regional Dynamics (2025-2034)

- Labeling Machine Market Driven by 3.84% CAGR (2025-34)

- Transit Packaging Market Insights 2025 Reveal Boxes and Cartons as Dominant Segment with Plastic Growing Fastest

- Flexible Paper Packaging Market Size Drives at 4.58% CAGR

- Digital Textile Printing Market Research, Consumer Behavior, Demand and Forecast

- Plastic Jar Packaging Market Size, Regional Data, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Box and Carton Overwrap Films Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA), Companies, Competitive Analysis, Value Chain & Trade Analysis 2025-2034

- Contract Packaging Market Competitive Strategies, Growth Opportunities and Industry Innovations

-

Paper Bag Packaging Market Size, Trends, and Forecast Analysis (2025-2034): Regional Insights, Market Segments, and Competitive Dynamics

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.